Digitally Connecting Hardware and Software – Toshiba’s Efforts to Solve Sustainability Issues

・It is important to use digital capabilities to connect hardware and software.

・Where is Toshiba focusing its R&D to enhance digital technologies?

・Getting the most out of digital with stakeholders, for the sustainability of people and the planet.

“DX is no longer a fad, it is a trend.” These were the words Mitsubishi Research Institute used in a report on the status of the corporate promotion of DX – digital transformation – and to summarize the factors behind its success. It is also often said that this the century of data, so it is no surprise that market researcher IDC has forecast, in “Data Age 2025,” that the volume of global data production generated annually will reach 175-zetabytes*1 by 2025.

*1: 1ZB = One trillion gigabytes; one followed by 21 zeroes.

Within this trend, Gartner, which researches technology trends, has emphasized the importance of “applying digital technology to sustainability.”*2 Their focus is on how to visualize and analyze huge amounts of digital data in order to solve sustainability issues like climate change and waste.

*2:Global CIOs, Lead Digital Sustainability to Drive ESG Performance

What this all boils down to is the question of how companies can create value by leveraging digital technology.

Nor is this emphasis on digital technology limited to businesses. In its Priority Policy Program, the Japanese government’s Digital Agency emphasizes that, “The digitalization of society as a whole will improve the convenience of people’s lives and streamline operations in the public and private sectors. Data utilization should be maximized for ‘people-friendly digitalization’ that is both safe and secure”. Essentially this means it is important that companies, universities, individuals, all levels of government, and other organizations all apply digital technology. This article looks at how Toshiba is doing that, and using digital technology to create value that will sustain people and the planet.

The Digital Agency’s Priority Plan foresees a society where no one is left behind and diverse happiness can be realized.

How to use digital tech to solve sustainability issues

The Apple Watch incorporates an electrocardiogram app that can detect atrial fibrillation, a cause of strokes. Apple-sponsored research by Stanford University School of Medicine found that the watch could detect early symptoms of atrial fibrillation that are often overlooked*3. The study led to development of a feature to notify users of irregular heartbeat, which has subsequently been improved with machine learning

*3:Marco V. Perez, et al. Large-Scale Assessment of a Smartwatch to Identify Atrial Fibrillation. N Engl J Med 2019;331: 1909-1917.

For people and the planet to be sustainable, it is very important that we collect data from hardware (like the Apple Watch), work on it with software (like the electrocardiogram app and machine learning), and thereby provide ourselves with meaningful information. This way of thinking is essential for finding solutions to sustainability issues.

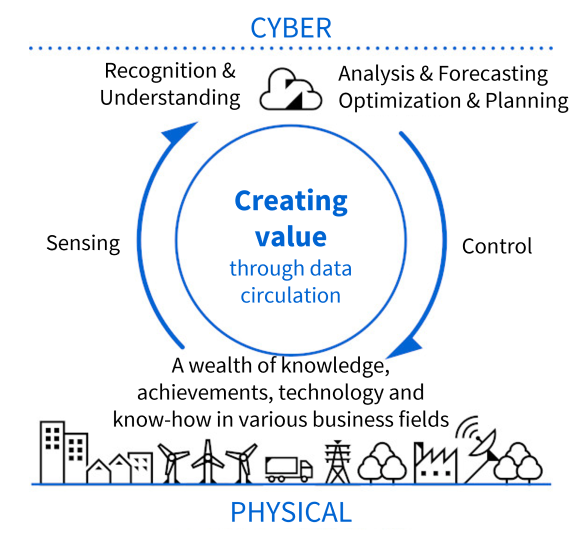

Toshiba’s strategy rests on using sensing to collect data in the real world, analyzing it in cyberspace, using the results to make predictions, formulating optimal plans, and returning valuable information to the real world. The reason why Toshiba can pursue this initiative is that almost 150 years in manufacturing has brought with it a deep wealth of experience, technology, and expertise in hardware, while over 50 years of AI research and development have allowed the company to thoroughly refine its software technology.

To solve sustainability issues, it is important to analyze real-world data and return it as valuable information.

How Toshiba uses digital technology to connect hardware and software

So how does Toshiba digitally connect hardware and software to create value? To find out we talked with Taro Shimada, Toshiba’s CEO. Shimada was long involved in aircraft design—hardware—and then honed his knowledge of software in his previous role at Siemens. He is confident in his understanding of what is required of companies today, and of what Toshiba should do.

“Toshiba is responsible for energy and social infrastructure that is in constant. Naturally, the reliability required of hardware is high, but we continue to meet that requirement. Our deep knowledge of hardware means that we know what kind of data it generates and how to visualize it and analyze the data with digital technology.

“This allows us to create diverse value grounded in the concept of digitally connecting hardware and software, such as adjusting energy supply and demand, and the efficient maintenance of bridges and other social infrastructure. Toshiba also has the capabilities, and track record, needed to develop world-first technologies one after another. Another thing is that we have an organizational culture based on mutual respect, with no use of honorifics, which means we can discuss things regardless of position or age, so innovations are constantly generated.”

Taro Shimada, Corporate Officer, President and Chief Executive Officer, Toshiba Corporation

At this point, before hearing more from Shimada, we should take a look at some examples of how Toshiba has linked hardware and software, and how they are being implemented in and contributing to society.

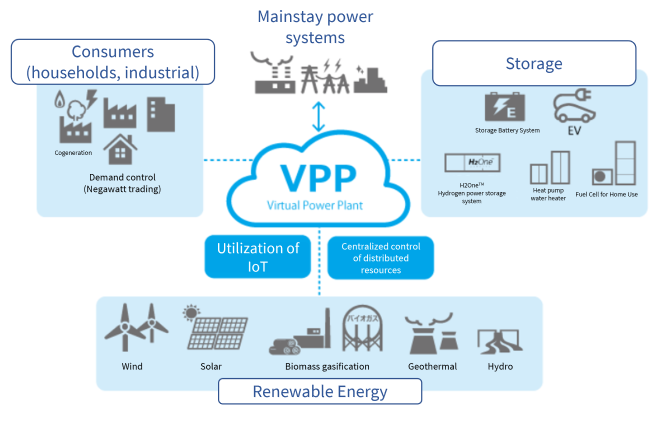

Virtual Power Plant (VPP)

Data is collected from distributed power sources—renewables like solar and wind power—from storage systems like rechargeable batteries, and from energy consumers. IoT is used to control all the equipment in real time, in response to the constantly shifting situation in electricity supply and demand, and it functions as if it were a single power plant.

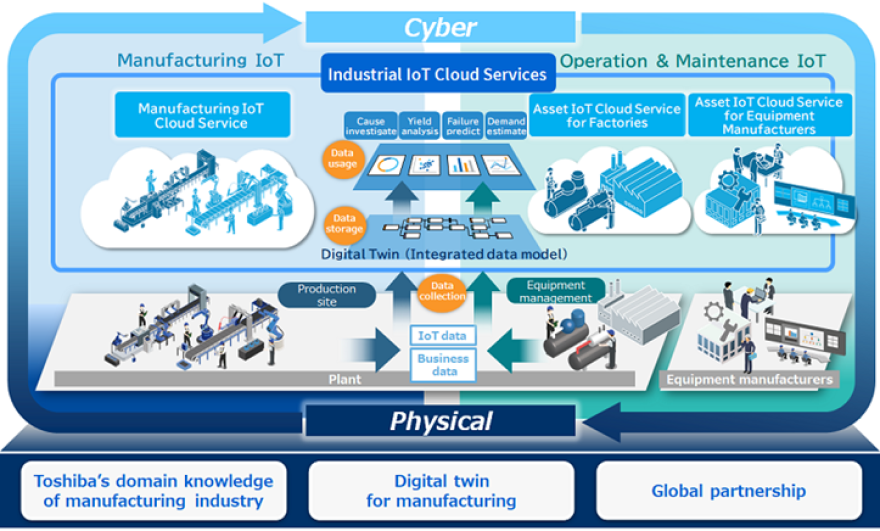

Industrial IoT Cloud Services

This solution constructs a digital twin which reproduces the real world in cyber space with IoT data from manufacturing equipment and factory facilities, and business data related to product design, development and manufacturing, and operation and maintenance (O&M). By linking data at high speed and visualizing, analyzing, and simulating changes in manufacturing conditions, traceability, and equipment operating conditions, the system improves manufacturing productivity and quality, increases the efficiency and advancement of O&M, and optimizes the overall value chain.

Details: Industrial IoT Cloud services, aiming for manufacturing DX

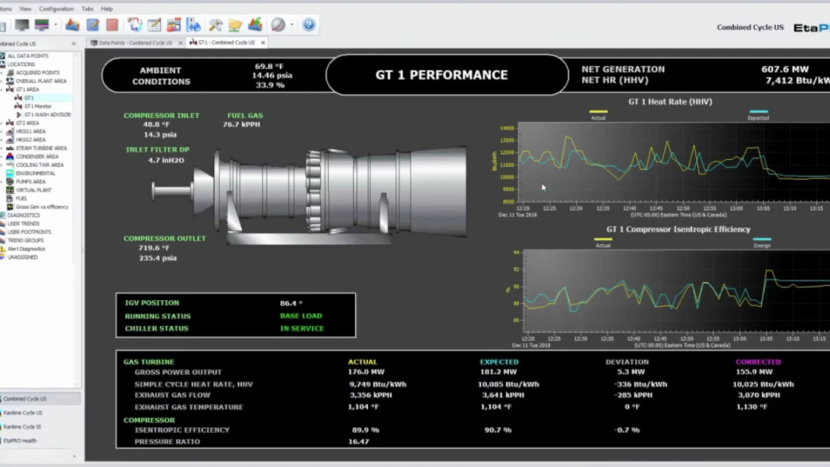

EtaPRO™ Plant Monitoring Software

This software solution monitors the thermal efficiency and operating conditions of power plants to detect signs of deterioration and abnormality. This makes possible timely maintenance and equipment replace, and realizes stable and highly efficient operation. It also minimizes energy losses due to equipment failures and power plant outages.

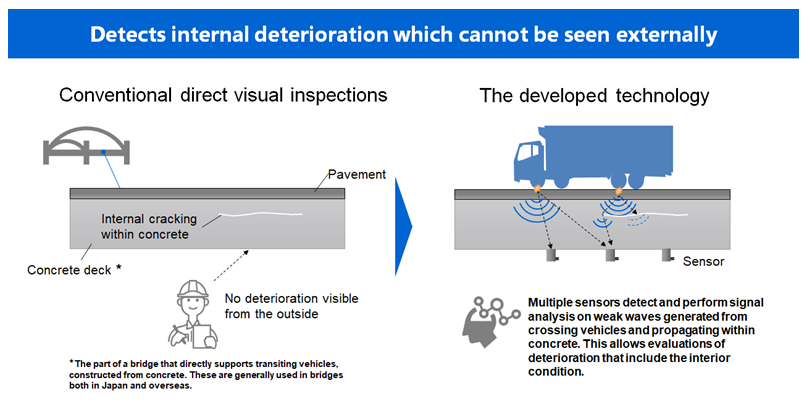

Measures against aging infrastructure

Deterioration in structures like bridges can be evaluated by detecting weak waves generated as vehicles pass over cracks inside the concrete, invisible externally. This supports more efficient repair work and extends the life of social infrastructure.

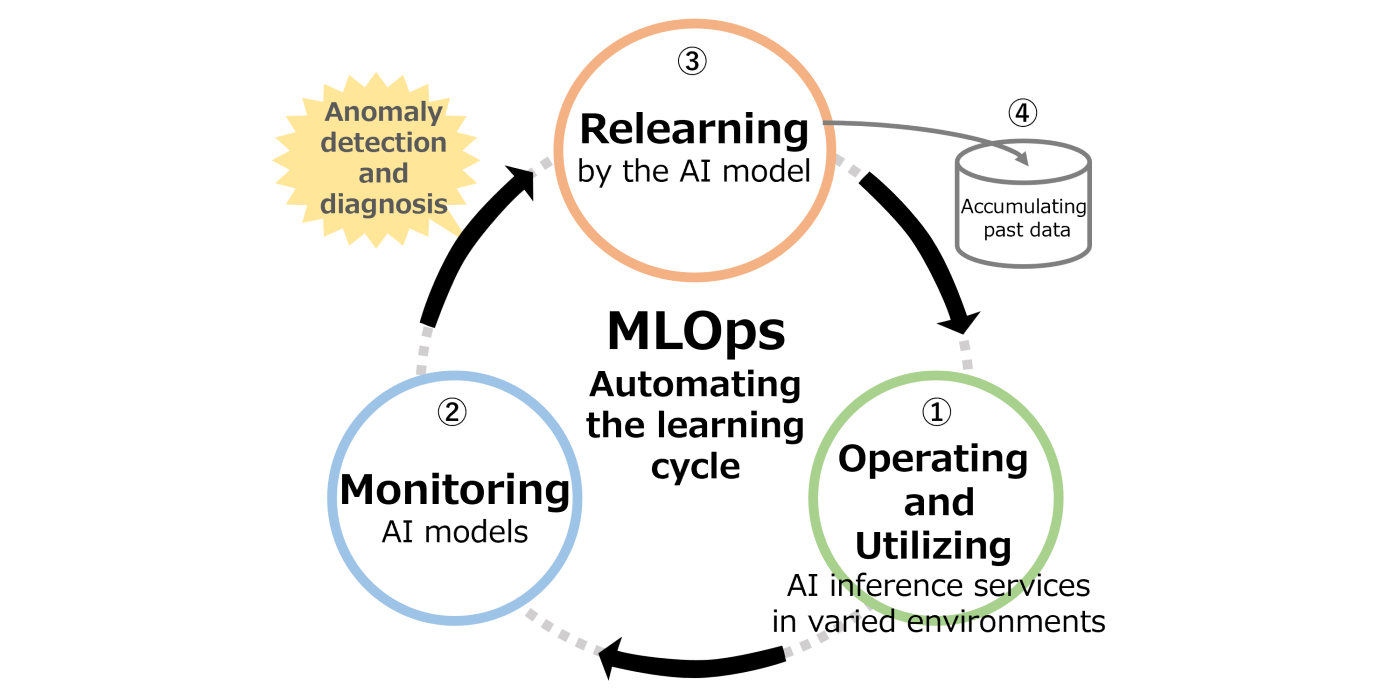

MLOps (Machine Learning Operations)

AI that is already deployed can be retrained with up-to-date data. ① Continue to operate the AI in various environments; ② monitor the situation for unexpected events; ③ use the data from the event to retrain the AI. It automatically improves in response to the actual situation and maintains performance.

Refining Digital Technology for the Sustainability of People and the Planet

While we have introduced a few representative examples of capabilities realized by linking hardware and software, there are still many more technology areas where work has to be done in order to solve social issues and move toward sustainability. Shimada discussed this, and where Toshiba will invest in research and development in order to enhance its thinking on digital know-how and technologies to ensure sustainability for people and the planet.

“At Toshiba, innovation something that happens every day from combining this technology and that technology. It’s mysterious, strange, and it’s interesting it’s, fun…it’s just one of those things. When I ask our researchers and engineers to do something big, maybe something that sounds unreasonable, they disappear for a while and then come back and say, “Look what I’ve made.” The more we dig into things, the wider our capabilities become.

“A part of Toshiba’s mission to solve sustainability issues is proactive investment in R&D, particularly in areas like communications security, renewable energy, and AI. We can leverage the power of digital technology to shape a new society, but the fundamentals of what our researchers and engineers do will not change. They respond to global challenges with technology, sustained by the venture spirit passed on since our founding in 1875, and with the feeling that ‘someone has to do this’.

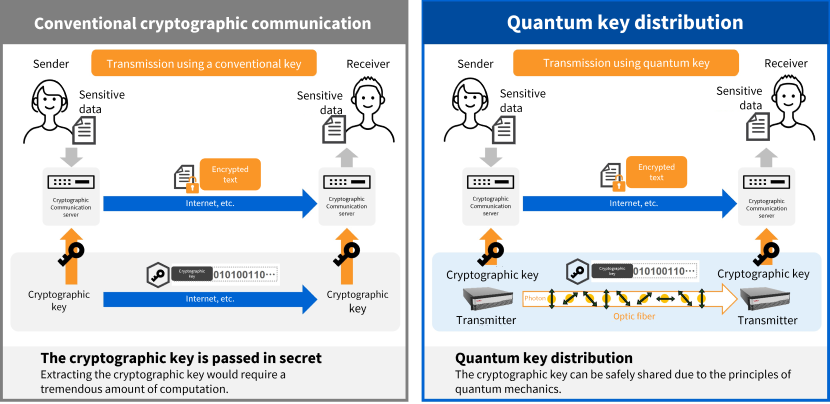

QKD (Quantum Key Distribution)

A technology that is used to distribute the encryption keys that are used to protect important confidential data. In QKD, encryption keys are transmitted over optical fibers in the form of photons, light particles. A feature of quantum mechanics is that photons undergo an unavoidable change in state when they come into contact with something, and using this property enables the indisputable detection of encryption key eavesdropping by a third parties.

Details: Quantum Key Distribution | Toshiba Digital Solutions Corporation

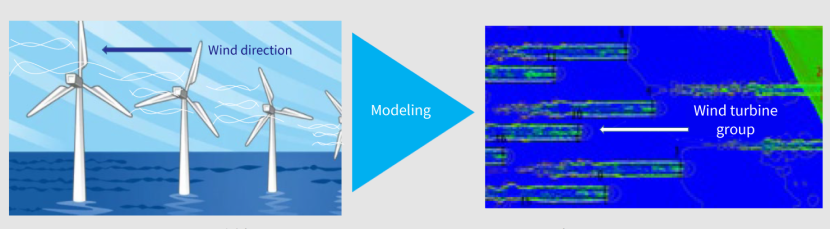

Wind Resource Analysis for Offshore Wind Turbines

This investigates wind conditions and ocean turbulence at potential offshore sites, to clarify the effects of wind speed deficits resulting from blade rotation of wind turbines located upwind of other turbines. Specifically, the analysis clarifies the economic impacts in terms of turbine durability and power generation, and contributes to the introduction of large-scale offshore wind farms.

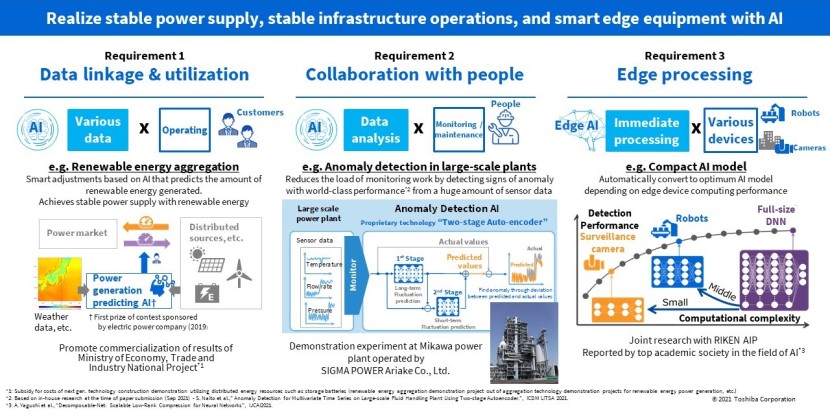

Artificial Intelligence (AI)

Toshiba develops AI that returns value to the real world. Its wide-ranging portfolio includes AI that ensures stable power supply by predicting power generation from renewables; that reduces loads on plant monitoring operations by detecting signs of anomaly in huge amounts of data; and that optimizes itself to equipment specifications by automatic downscaling the AI model.

Details: Toshiba AI Technology Catalog

Up to this point we have looked at the importance of connecting hardware and software digitally in solving sustainability issues, and at how Toshiba is creating value and enhancing its digital capabilities. As already mentioned, an important element of the Digital Agency’s Priority Policy Program to make humanity and the Earth sustainable is that all stakeholders, including companies, universities, individuals, and governments, utilize digital technology in their respective spheres. With this in mind, we asked Mr. Shimada about the implications of Toshiba’s utilization of digital technologies.

“As I said, one of Toshiba’s strengths lies in the ability to constantly create diverse technologies. As sustainability issues like climate change become more serious, I truly believe it is important for companies like Toshiba to stay vibrant and play an active role.

“We will continue to leverage the strengths of digital technologies in the fields of energy and social infrastructure. Our success in value creation for close to 150 years will help to lead the way toward a brighter tomorrow, and the realization of carbon neutrality, and a circular economy. We will continue to work together with our stakeholders to put into practice the Basic Commitment of Toshiba Group: ‘Committed to people, committed to the future’.”

Toshiba is using digital technology to connect hardware and software and to continue to create rich value, in order to contribute to the lives and cultures of people around the world. This aligns perfectly with people-friendly digitalization that aims to create a society where no one is left behind and diverse forms of happiness can be achieved.

Find out more about Toshiba:

Global Top Page / Toshiba

Toshiba’s AI Technologies

Toshiba’s Quantum Technologies

Toshiba’s Technologies in the Industrial IoT Space

Toshiba’s Approach in Getting the Best from Reliable Hardware with Software Defined